Structure of Natural Timber

- Natural timber is a natural composite material comprising cellulose fibres in a lignin matrix.

Moisture content of natural timber

When living trees are cut down the timber is of very little use in engineering, product design and so on. This is due to the moisture (or greenness) of the wood. Most of this moisture needs to be removed and a equilibrium moisture content achieved. In order to achieve this timber needs to be seasoned.

- Absorbed moisture is the moisture contained in the cell walls of timber.

- Free moisture is the moisture contained within the cell cavities and intercellular spaces.

- Equilibrium Moisture content (EMC): This is when the moisture content of wood is at equilibrium (same as) the local environment. This can be affected by humidity and temperature changes.

Seasoning

- Seasoning is the commercial drying of timber which reduces the moisture content of wood.

- Thus making the timber highly useable.

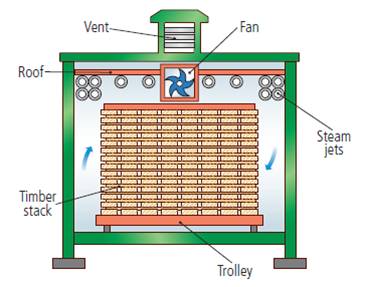

- Kiln seasoning is carried out in a thermally insulated chamber, a type of oven, that produce the appropriate temperatures to complete the processes, such as hardening, drying, or chemical changes.

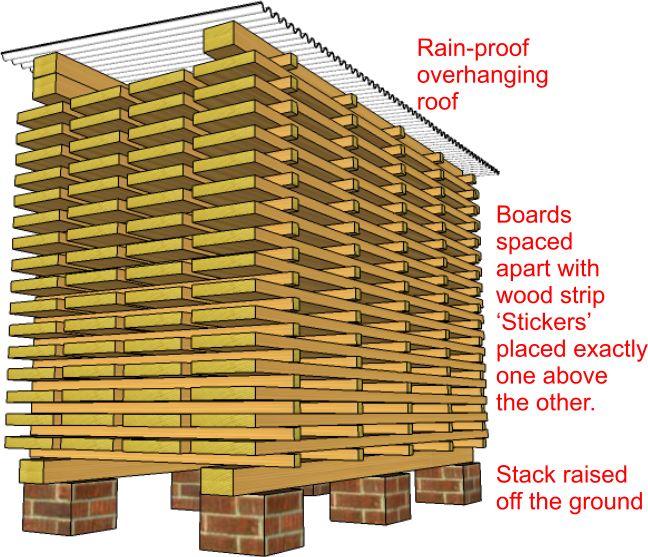

- Air-drying: Air- drying are stacks of sawn timber in the open or in large sheds. There is little control over the drying process as the weather elements have affects.

- Kiln-drying are stacks of sawn timber in a kiln, to reduce the moisture content in wood, where the heat, air circulation, and humidity is closely controlled.

Timber Defects

While the moisture content of ‘wet’ timber is being removed defects may occur, some of which are listed below. Controlled seasoning can avoid this. However, once the EMC is achieve is timber goes from high humidity to low humidity (uncontrolled) then the defects will occur.

- Warping is the distortion in wood caused by uneven drying, which results in the material bending or twisting.

- Bowing is the warping along the length of the face of the wood.

- Cupping is the warping across the width of the face of wood, in which the edges are higher or lower than the centre.

- Twisting is the warping where the two ends of a material do not lie on the same plane.

- Knots are imperfections in timber, caused by the growth of branches in the tree that reduces its strength.

|

Natural timber

Is timber that is sawn from the tree and is used as is (ie not made into plywood, etc). This includes hardwood and softwood trees.

Characteristics of natural timber

- Tensile Strength: The tensile strength of natural timber is greater along the grain than across the grain.

- Resistance to damp environments: is very resistant.

- Longevity: Hardwoods very good. Softwoods good.

- Aesthetic properties: natural colours range (red, purple, cream and brown). The grain can add to its aesthetics.

- Also known as Engineered board or composite wood

- Man-made timber include:

- Plywood (Laminated boards) are layers of veneers (very thin slices of wood) glued together perpendicularly.

- Particle board (Chipboard) which is made from different sizes of wood chips, joined with glue and pressed.

- MDF (Medium Density Fibre Board) strands of fibre ruled together and pressed into sheets.

-

- Man-made timber often requires finishing such as painting or lamination.

- Lamination is the covering the surface with a thin sheet of another material (plastic laminate, wood veneer, etc) typically for protection, preservation or aesthetic reasons.

Characteristics of man-made timber

- Tensile strength: depends on the man-made timber

- Plywood – high tensile strength in all directions

- Particle board and MDF – very low

- Resistance to damp environments: depends on the man-made timber.

- Exterior plywood – excellent.

- Interior plywoods very low

- Particle board and MDF – very low

- Longevity:

- Plywood is high

- Particle board and MDF is low to medium

- Aesthetic properties:

- Plywood if the top layer is of a nice timber like Beech will be good

- Particle board and MDF requires finishing or a sheet of lamination (see previous section)

Treating and finishing timbers

Treatment of wood can involve using solutions. The reasons for treating or finishing wood include:

-

- Reducing attack by insects, fungus and marine borers by making the wood poisonous

- Creosote: A material that penetrates the timber fibres protecting the integrity of the wood from attack from borer, wood lice and fungal attack.

- Reducing attack by insects, fungus and marine borers by making the wood poisonous

- Protection from the weather

- Protection from Dry rot.

- Where timber is subjected to decay and attack by fungus.

- Improving chemical resistance

- Enhancing aesthetic properties

- Modifying other properties

Recovery and disposal of timbers

- Wood recycling is the process of turning waste timber into usable products.

- Recycling timber is a practice that was popularized in the early 1990s as issues such as deforestation and climate change prompted both timber suppliers and consumers to turn to a more sustainable timber source.

- Reforestation is the process of restoring tree cover to areas where woodlands or forest once existed. If this area never returns to its original state of vegetative cover the destructive process is called deforestation.

Design contexts

Structural design contexts

- Buildings – framing for walls or roofs.

- Flooring – would typically use hardwoods because of aesthetics and their longevity (durability).

Aesthetic design contexts.

-

-

- Furniture

- Children’s toys.

-

International Mindedness

The demand for high-quality hardwoods results in the depletion of ancient forests in some regions/countries impacting on the environment in multiple ways.

Theory of Knowledge

Designers are moving from exploitation

of resources towards conservation and sustainability. Is the environment at the service of man?